86-574-62189988

Xinlang West Road, Industrial Park, Yuyao, Ningbo, Zhejiang, China (Mainland)

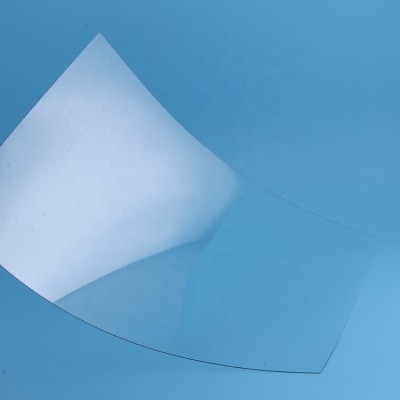

0.2mm/0.3mm/0.5mm PC film/Polycarbonate film for electronic and printing, US $ 3.6 - 6 / Kilogram, Zhejiang, China, BEIER SOLA, JIASIDA*PW-UL.Source from Yuyao Jiasida Sun Sheet Co., Ltd. on Waimaotong.com.