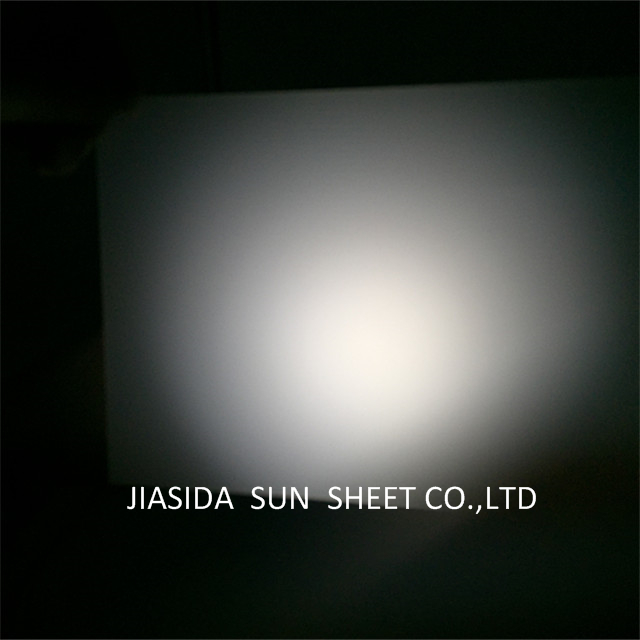

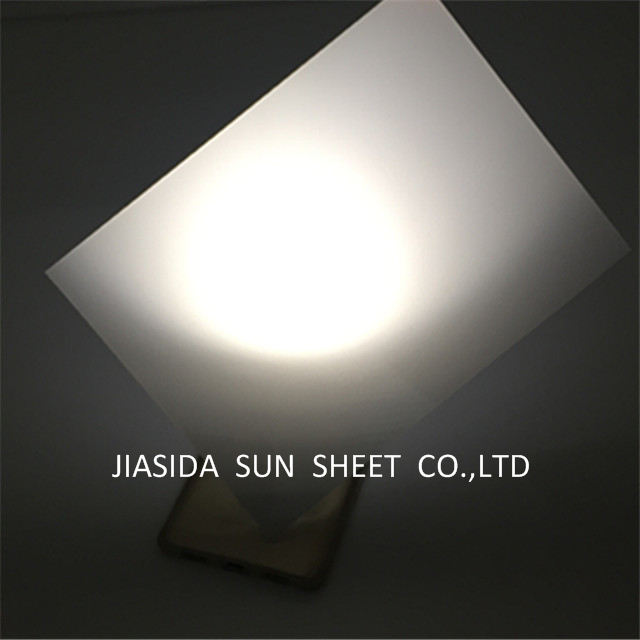

0.8mm, 1.5 mm Polycarbonate Light Diffusion Sheet for LED Light, ceiling, PC DIFFUSER for advertising panel

Product Description

Description of PC Diffusion sheet, PC diffuser

Width: 1220,1830,2050,2100mm, the Max width is 2100mm.

Length: No limit (Recommend 5800, 6000, 11800,12000mm to suit 20'container &40'containe.

Standard size: 1220*2440mm, 2100*5800mm

Quality:100% virgin Lexan raw material.

| Product Model | Surface Texture | Color | Thickness Range | Standard Thicnkness |

| JIASIDA*SG11W | Both sides polished | White | 0.5-10 mm | 1.0 1.2 1.5 mm 2.0 3.0 |

JIASIDA*SG41W | One side velvet, one side polished | 0.5-6 mm |

| JIASIDA*SG42W | One side velvet, one side matte | 0.5-3 mm |

| JIASIDA*SG**HT | / | Light White | 0.5-3 mm |

| JIASIDA*SG**W-F | / | White | Flame Retardant Grade PC Diffuser Sheet |

Technical Parametere

Technical features: ( polycarbonate light diffusion ):

1) Impact strength: 850J/m ,the impact strength of solid PC sheets is 250 times

that of glass, 20-30 times of PMMA sheet

2) Light transmission: 80%-90% for different thickness of clear color

3) UV resistance:50μm thickness UV layer, the sheet can filter 99% ultraviolet radiation in sunlight

4) Specific gravity: 1.2 g/cm

5) Coefficient of thermal expansion: 0.065 mm/moC

6) Service temperature: -40oC to 120oC

7) Heat conductivity: 2.3-3.9 W/m2 oC

8) Tensile strength: >60N/mm2

9) Flexural strength: 100N/mm2

10) Modulus of elasticity: 2,400mPa

11) Tensile street at break: >65mPa

12) Elongation at break: >100%

13) Specific heat: 1.16J/kgk

14) Heat deflection temperature: 140oC

15) Soundproof index:4mm thickness--27dB,5mm--28dB,6mm--29dB

Applications

Application:( polycarbonate light diffusion ):

♦ Retail Displays

♦ Airport Signage

♦ Point of Purchase Displays

♦ Bus Shelter Advertising

♦ Way Finding Signage

♦ Interior Lighting

♦ Display Shelves

♦ Trade Show Exhibits

♦ Protection Screen

♦ Lampshade

♦ LED light, LED box

Packaging & Shipping

Packaging & Shipping:

Company Information

Company Information:

Jiasida is a factory of Polycarbonate Sheet, have 10 lines of production, 4 production lines hollow sheet, 2 lines solid sheet, 2 lines pc film, in addition, we have one line corrugated sheet and one accessories production line.

Our Factory can produces 8-15Tons sheet per line per day.

Our Raw Material is 100% Virgin Sabic Material.

We have perfect management:

1. Raw Material Inspection

2. In Process Quality Contrl

3. Finished Product Inspection

We have a laboratory to develop new products.

FAQ

FAQ:

Q – What is the fire rating of Polycarbonate sheet ?

Class B1 fire rating which is an excellent fire rating.

Q – Is the Polycarbonate sheet unbreakable?

The material is virtually unbreakable, and will resist most impact resistant situations, however they will not guarantee 100% the material is unbreakable, for example if the material was to be in an explosive situation or to be used in a ballistic situation.

Q – Can I cut Polycarbonate sheet at home and I do need any special tools?

You can use our cut to size service to save the hassle of cutting, however if you do need to cut the panels at home you can use a jigsaw, Band Saw and fret saws.

Q – How can I clean my polycarbonate sheet ?

Do not use abrasive materials as will affect the material, the best advice is to use warm soapy water with a soft cloth.

Q – What is the difference between Polycarbonate sheet and Acrylic sheet ?

The main difference between the two is Polycarbonate is virtually unbreakable, acrylic is much stronger than glass, but it will break/shatter if force is applied. Polycarbonate is a class 1 fire rating where Acrylic is a class 3 / 4 fire rating.

Q – What is the difference between Polycarbonate and Lexan ?

There is no difference, Lexan is a brand name for Polycarbonate sheet, other common brand names relating to Polycarbonate sheet include Makrolon, Marlon, Palsun and quinn.

Certifications

Certifications:

we supply polycarbonate sheet, solid sheet and finished product.

more we supply is the best suitable solution for you.